News

May 29,2025

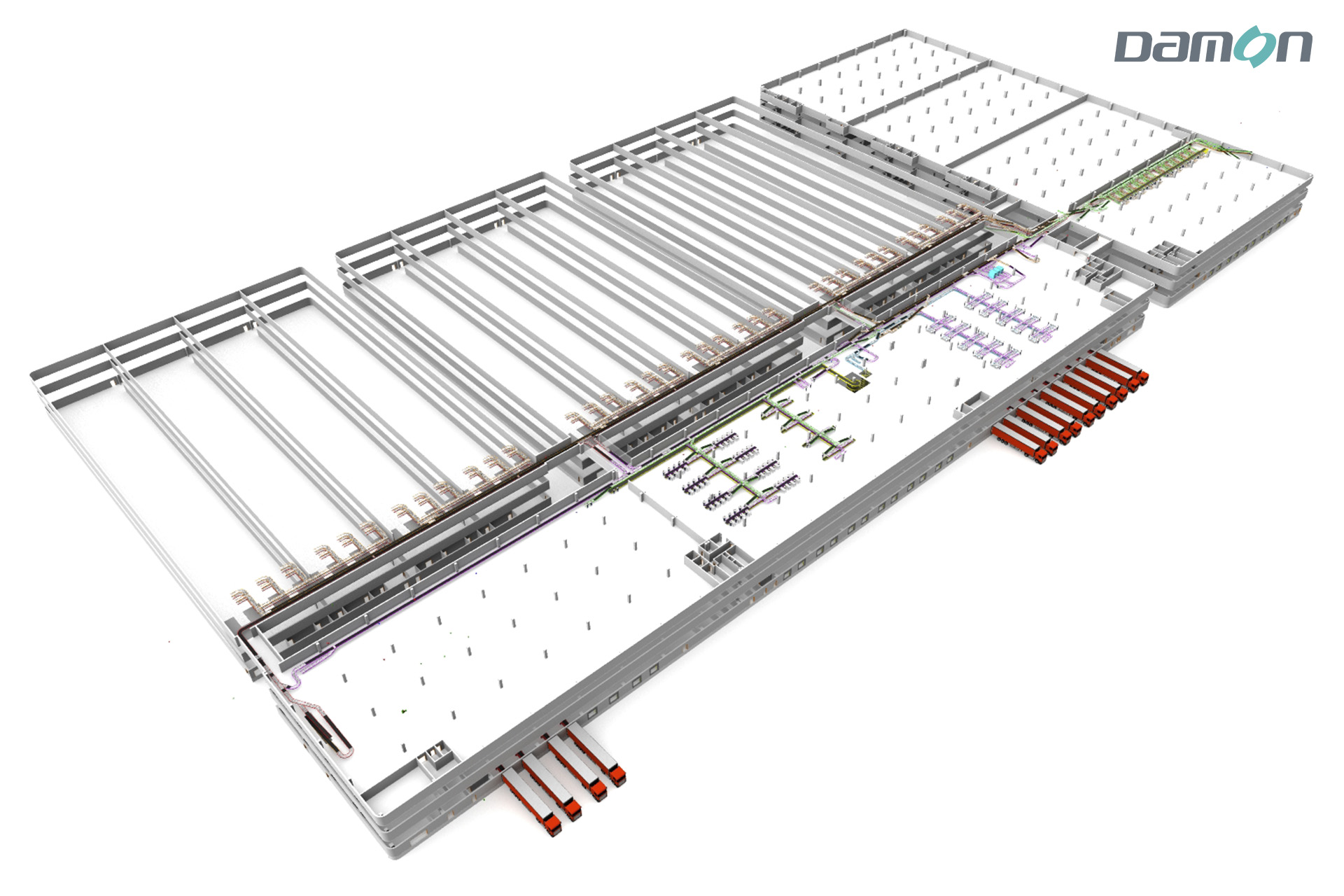

Damon Powers Suzhou Anta International Integrated Operation Center Project to Set Sail

Recently, Damon Suzhou Anta International Integrated Operation Center intelligent conveying and sorting system project officially started construction. Members of Anta International Integrated Operation Center project team, Damon Anta series project team, and cooperative suppliers involved in this project gathered in Suzhou to jointly open delivery new chapter of this project conveying and sorting section, injected new impetus into the global development of Anta's logistics supply chain.

Suzhou Anta International Integrated Operation Center project is not merely a logistics construction project, but also an innovative practice in the shoe and clothing industry. Damon is honored to be a partner in the construction of Suzhou Anta International Integrated Operation Center project, undertakes the transportation and sorting tasks that connect various logistics functional areas. Damon Anta series project team stated at the groundbreaking ceremony: "Damon is committed to working hand in hand with partners in the upstream and downstream of smart logistics industry chain to build this project into a new benchmark of shoes and clothing smart logistics, setting a typical example worth learning from for the industry and facilitating shoe and clothing logistics towards digitalization and intelligence transformation and upgrade."

Looking back on the project's progress, it has been infused with the wisdom and hard work of many Damon engineers. From the business team's successful acquisition of this project despite numerous difficulties, to the orderly progress of engineering design work, and then to smooth conclusion of the factory acceptance test of core products... With a professional spirit of striving for excellence, Damon technical team has fully discussed with Anta team, deeply explored customer needs, arranged detailed designs in advance, and continuously optimized the plan to gain time for downstream electromechanical design. These solid preparatory works have laid a solid foundation for the official start of Suzhou Anta project.

In fact, in order to actively respond to the strict requirements of customers for equipment operation, Damon delivery team had already prepared a series of "tight at front and pressing at back" execution strategies for Suzhou Anta project before this kick-off ceremony. They had formulated detailed implementation plans and risk emergency response plans, and in combination with project scale, they had made advance preparations for the standard models of self-developed products,quickly lock in factory design and production resources, reserve production capacity, including locking orders for key materials in advance and preparing core equipment in batches, and give priority to pushing them down. Meanwhile, Damon project team coordinated in advance the resources for mechanical and electrical installation and commissioning to guarantee high efficiency delivery.

To help Anta take a crucial step in its international logistics network layout, Damon will give full play to its own advantages, fully integrate its high-quality resources, and rely on its years of technological accumulation in the field of logistics automation and innovative applications in the logistics scenarios of shoe and clothing industry. It will closely collaborate with key partners in the upstream and downstream to quickly respond to Anta's demands, strictly control the progress and quality of project implementation. Facing on-site implementation key nodes and project difficult issues, Damon delivery experts will form a special technical breakthrough team to stay on the front line for tracking and promptly respond to the sudden challenges encountered during project rectification and change process.

Project implementation stage was fraught with difficulties. Next, Damon team, which has extensive experience in successfully delivering major projects in the shoe and clothing e-commerce industry, will arrange semi-complete shipment of core equipment and on site cross-installation of drive part, and at the same time, make advance arrangements for electrical control simulation and virtual debugging to guarantee that the core system can be quickly debugged and operate normally on site. In addition, to guarantee project delivery date, when necessary, the quality team will conduct on-site quality supervision. This not only guarantees the high-quality delivery of core equipment but also shortens the shipping, mechanical and electrical installation cycle by 30%, guarantees highly efficient contract fulfillment and provides strong support and guarantee for logistics and shipping efficiency of this project.

The launch of Suzhou Anta International Integrated Operation Center project is an important milestone in the development of Anta Group and also a new starting point for the in-depth cooperation between Damon and Anta. In the future, Damon will continue to provide customers with scenario-based intelligent logistics system solutions and contribute significant force to footwear and apparel supply chain’s high-quality development.

Share to: